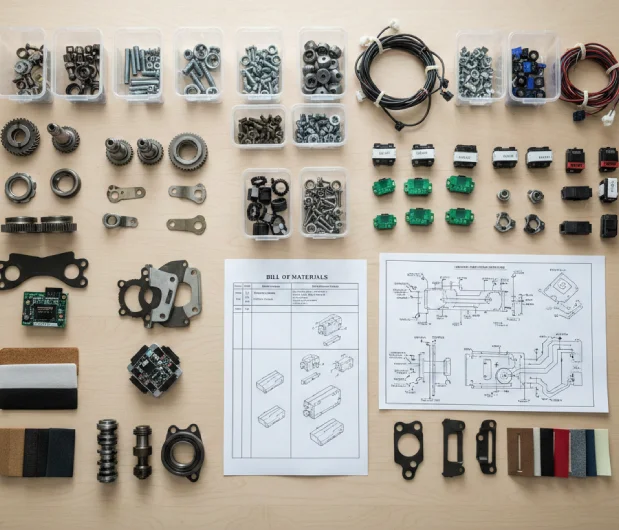

Bill of Materials (BOM) Preparation

IMARC Engineering delivers comprehensive Bill of Materials preparation services that transform manufacturing specifications into precise, actionable material requirements supporting efficient production operations. Our specialized team combines deep technical expertise, manufacturing knowledge, and systematic methodologies to develop accurate BOMs that optimize procurement, control costs, and ensure seamless production workflows.

With experience across pharmaceuticals, food processing, chemicals, engineering products, and consumer goods, we develop BOMs covering material hierarchies from raw materials to finished products. Our approach includes specification definition, quantity calculation, supplier identification, cost estimation, and documentation standardization, ensuring integration with procurement and inventory systems.

From new product development requiring initial BOM creation to manufacturing optimization through restructuring or legacy system modernization, we partner with manufacturers to deliver accurate material documentation. Our services include specification development, data management, validation, and maintenance, enabling precise procurement planning, preventing shortages, reducing excess inventory, and supporting efficient manufacturing operations.

Our BOM Development Methodology

Our structured BOM preparation framework combines comprehensive product analysis, detailed material specification, systematic quantity determination, and rigorous verification processes. This proven methodology ensures development of accurate BOMs supporting efficient procurement, production planning, and inventory management across manufacturing operations.

Product Analysis & Structure Definition

Understanding product design, manufacturing processes, and assembly sequences to establish hierarchical BOM structures accurately representing material requirements and production workflows.

Material Specification & Quantity Calculation

Identifying precise material specifications, calculating accurate quantities accounting for process losses, and establishing alternative material options supporting procurement flexibility.

Cost Estimation & Supplier Identification

Developing material cost estimates, identifying qualified suppliers, and establishing procurement parameters supporting accurate financial planning and efficient material sourcing.

Documentation & System Integration

Creating standardized BOM documentation, configuring ERP system integration, and establishing change management protocols ensuring accuracy, accessibility, and ongoing BOM maintenance.

Why Choose IMARC for Bill of Materials Preparation

Our BOM preparation expertise transforms material requirements planning into strategic advantages through systematic development, comprehensive verification, and integration excellence. This proven approach eliminates procurement errors, optimizes inventory management, and establishes accurate foundations supporting efficient manufacturing operations and financial planning.

Precision Engineering & Technical Accuracy

Ensure absolute accuracy through systematic material specification, quantity verification, and quality control processes. Our engineering rigor eliminates costly errors, reduces rework, prevents production delays, safeguards compliance, and minimizes material waste across programs.

Manufacturing Process Understanding

Benefit from deep manufacturing knowledge spanning diverse production processes. We account for process-specific considerations, including material losses, scrap factors, and production variability, ensuring realistic quantity determinations aligned with actual operating conditions.

Comprehensive Multi-Level BOM Structures

Develop complete hierarchical BOMs addressing complex assemblies, sub-assemblies, and component relationships. Our structured approach supports modular manufacturing, variant management, and flexible production planning.

Cost Optimization & Procurement Efficiency

Maximize value through strategic material selection, supplier identification, and alternative material documentation. Our cost-conscious approach identifies optimization opportunities reducing material expenses without compromising quality.

ERP System Integration Expertise

Ensure seamless integration with enterprise resource planning systems, manufacturing execution systems, and inventory management platforms. Our technical expertise establishes robust data structures supporting automated procurement, accurate inventory control, and reliable production planning.

Ongoing Maintenance & Change Management

Establish systematic BOM maintenance protocols managing design changes, material substitutions, and continuous improvements. Our change control frameworks maintain BOM accuracy throughout product lifecycles supporting operational continuity.

Specialized BOM Preparation Across Manufacturing Sectors

IMARC Engineering delivers industry-specific Bill of Materials preparation services addressing unique sector requirements, regulatory considerations, and production methodologies. Our deep understanding of industry-specific materials, specifications, and manufacturing processes ensures development of accurate, compliant BOMs supporting efficient operations across diverse manufacturing sectors.

Specialized pharmaceutical BOM preparation including active pharmaceutical ingredients, excipients, packaging materials, and labeling components. Our expertise covers formulation BOMs addressing batch calculations, master formula records, regulatory compliance documentation, and change control protocols ensuring accurate material specifications for tablets, capsules, injectables, and ointments supporting GMP compliance, batch record generation, and regulatory submission requirements across pharmaceutical manufacturing operations.

Specialized food and beverage BOM preparation including recipe formulations, ingredient specifications, packaging materials, and labeling components. We develop comprehensive BOMs addressing food ingredients, processing aids, additives, packaging systems, and regulatory labeling supporting food processing, beverage manufacturing, and packaged goods production ensuring accurate specifications, allergen management, nutritional calculations, and regulatory compliance across food manufacturing from recipe development through commercial production.

Effective chemical BOM preparation for specialty chemicals, industrial chemicals, formulated products, and chemical intermediates. Our services address raw material specifications, catalyst requirements, solvent selections, and packaging materials supporting chemical synthesis, blending operations, and formulated product manufacturing ensuring accurate material balances, process specifications, and safety considerations across diverse chemical manufacturing including agrochemicals, polymers, and specialty formulations.

Technology product BOM preparation including electronic assemblies, printed circuit boards, software-hardware integrations, and consumer electronics. We develop detailed component lists addressing semiconductors, passive components, connectors, enclosures, and packaging materials supporting electronics manufacturing, assembly operations, and testing requirements ensuring accurate specifications, component sourcing, and production planning across technology products from prototypes through mass production.

BOM preparation for power generation equipment, renewable energy systems, electrical components, and energy infrastructure. We develop comprehensive material lists addressing electrical components, mechanical assemblies, control systems, and installation materials supporting solar installations, wind turbines, battery systems, and power distribution equipment ensuring accurate specifications, supplier coordination, and project execution efficiency across energy sector manufacturing and installation operations.

Agricultural product BOM preparation for processed foods, agricultural inputs, specialty ingredients, and packaged goods. Our services develop comprehensive material lists addressing raw agricultural commodities, processing aids, preservatives, packaging materials, and labeling components supporting food processing, ingredient formulation, and agricultural product manufacturing ensuring accurate specifications, traceability requirements, and regulatory compliance across agricultural manufacturing operations from farm inputs through consumer packaged goods.

Automotive component BOM preparation including mechanical assemblies, electrical systems, interior components, and finished vehicle assemblies. We develop detailed multi-level BOMs addressing engineered components, purchased parts, fasteners, fluids, and finishing materials supporting automotive manufacturing, assembly operations, and supply chain coordination ensuring accurate specifications, just-in-time delivery requirements, and quality control protocols across automotive production from component manufacturing through vehicle assembly.

Infrastructure material BOM preparation for construction products, building systems, prefabricated components, and infrastructure assemblies. Our services address construction materials, structural components, finishing materials, and installation hardware supporting building material production, modular construction, and infrastructure manufacturing ensuring accurate quantity takeoffs, material specifications, and procurement planning across infrastructure projects from construction materials through prefabricated building systems.

Optimal BOM preparation for engineering products, industrial machinery, precision components, and manufactured assemblies. We develop multi-level BOMs addressing complex mechanical assemblies, electrical components, fasteners, and finishing materials supporting diverse manufacturing operations from automotive parts through industrial equipment ensuring accurate material specifications, supplier coordination, and production efficiency across mechanical engineering and industrial manufacturing applications.

Trusted by Industry Leaders

We partner with global enterprises and ambitious businesses across sectors to deliver operational excellence, strategic insights, and sustainable growth through integrated solutions.

Success in Their Words

Real feedback from clients across industries. Discover how our solutions delivered measurable impact and operational excellence.

Frequently Asked Questions

We have compiled answers to critical questions manufacturers, operations managers, and business leaders ask about Bill of Materials preparation and material requirements planning. These insights address BOM development processes, accuracy considerations, system integration, maintenance practices, and strategies for effective material management.

Ready to Optimize Your Material Requirements Planning?

Contact our engineering team today to discuss your Bill of Materials needs and discover how IMARC Engineering can establish accurate, efficient material planning supporting your manufacturing excellence.